+86-18962276627 seals@hq-seal.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

English English

EnglishViews: 0 Author: Site Editor Publish Time: 2022-03-21 Origin: Site

01. Causes of liquid film cavitation

Between the end faces of the mechanical seals operating at high speed, the micro-modeling and deformation of the sealing end faces lead to the contraction and expansion of the flow channel, which is easy to cause cavitation in the micro-gap liquid film.

02. Definition of liquid film cavitation

Refers to the process of forming vapor cavitation in the low pressure region of the liquid flow field. The cavitation in mechanical seals includes gas-phase cavitation and vapor-phase cavitation. There are macroscopic cavitation and microscopic cavitation. When the local pressure of the liquid film on the sealing surface drops to the saturated vapor pressure, the gas nuclei in the liquid are released to form bubbles, which is gas-phase cavitation; when the liquid itself partially vaporizes to form bubbles, it is vapor-phase cavitation.

03. Application Status of Liquid Film Cavitation in Mechanical Seals

Cavitation has an important influence on the friction performance (or lubricating performance) and service life of mechanical seals. Scholars at home and abroad have carried out many years of experimental research and theoretical exploration on the cavitation phenomenon of mechanical seals, and have made beneficial progress. However, most of the current mechanical seal theoretical analysis and calculation and actual product design ignore the cavitation phenomenon. This situation It has become one of the obstacles for high-performance mechanical seals to achieve new breakthroughs. The generation and collapse of bubbles have a great influence on the distribution, bearing capacity and stability of the liquid film pressure.

04. Difference Between Cavitation and Vaporization

Cavitation is a physical phenomenon that is mainly affected by local pressure changes. Different from liquid film cavitation, vaporization is the phenomenon in which the liquid film on the end face of the mechanical seal changes from liquid phase to vapor phase. It is the result of the combined effect of boiling and flash evaporation.

05. The formation process of cavitation in mechanical seals: (macro cavitation)

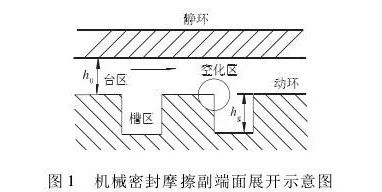

The above picture is a schematic diagram of the end face of the mechanical seal friction pair with shallow grooves. Due to the opening of the shallow grooves, the sealing end face forms a convergence area and a diffusion area. When the liquid flows from the platform area to the groove area, the flow channel converges and the pressure rises; When the liquid flows from the platform area to the trough area, the flow channel expands, and a low pressure area appears. When the pressure drops to the saturated vapor pressure, local liquid vaporization or dissociation of dissolved gas occurs, causing cavitation and even cavitation.

06. The formation process of cavitation in mechanical seals: (microscopic cavitation)

Because the mechanical seal gap flow is on the micrometer scale, the continuum hypothesis no longer applies when the characteristic size of the channel is related to the mean free form of the fluid molecules, and the relative importance of the various forces affecting the flow changes. In addition, the surface roughness of the microchannel, which is often neglected due to its small influence in the conventional scale, has a non-negligible influence in the microscale flow. Small disturbances often caused by surface roughness can affect the flow of the entire main flow area, which is also the main reason for the cavitation of the mechanical seal micro-gap liquid film.

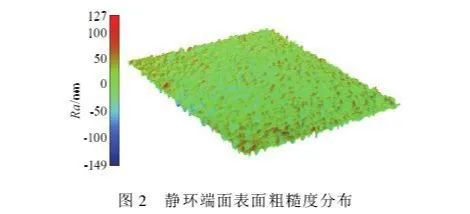

The above picture is the irregular surface roughness distribution of the end face obtained by measuring the surface of the static ring of the friction pair with a non-contact optical profilometer. The asperities on the sealing surface can be assumed to be quasi-cylindrical. When the liquid flows through the sealing end face, a low-pressure region will be formed behind the asperities, and surface cavitation will occur when the pressure is lower than the saturation pressure. In addition, the scale effect of micro-scale flow, surface tension, fluid viscosity, etc. will also have an impact on micro-cavitation.

07. Influence of end face liquid film cavitation on sealing performance

The non-contact of the end face of the mechanical seal mainly depends on the static pressure effect and dynamic pressure effect of the liquid film. Relevant studies have shown that the existence of cavitation makes the liquid film not lose its bearing capacity due to the offset of positive and negative pressures. Etison et al. believe that cavitation is an important reason for the formation of end face opening. In addition, due to the cavitation generated on the end face of the liquid film, the leakage of the end face can be prevented and the friction of the end face can be reduced to achieve cavitation drag reduction.

However, under the condition of high speed, serious cavitation will occur. When the cavitation reaches a certain level, the end face will lose the opening force, the sealing end face will lose the opening force and even the sealing face will fail. And with the development and collapse of cavitation, cavitation will also occur on the sealing surface, which will destroy the sealing surface.

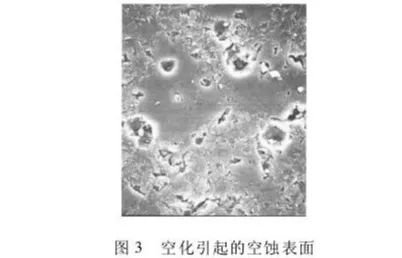

The above picture shows that Tsunenori et al. used a profilometer to observe the graphite surface damaged by cavitation, and found that cavitation increased the surface roughness.